In today’s fast-paced world manufacturing is like walking over a tightrope that requires a delicate balance between managing resources and profitability. For small and medium-sized manufacturers, unique challenges often threaten to disrupt this delicate equilibrium.

Here’s where Microsoft Dynamics 365 Business Central steps in as a reliable safety net. It provides smart solutions that directly address the challenges, empowering manufacturers to streamline their operations and enhance efficiency.

In this blog, we will explore the specific hurdles faced by small and medium-sized manufacturers and unveil how Dynamics 365 Business Central transforms these challenges into opportunities for growth and success.

Challenge 1: Overproduction – The Hidden Drain on Resources

Overproduction, the age-old nemesis of manufacturing, is like pouring water into a cup that is already full. When production exceeds demand, it ties up capital and wastes valuable resources like labour and energy. For small manufacturers with limited capacity, this inefficiency can create bottlenecks and strain their finances.

The Solution:

Dynamics 365 Business Central eliminates the guesswork with real-time production schedule. By syncing schedules with sales orders and forecasts, it ensures that production levels align with actual demand. These automated adjustments keep operations agile, helping manufacturers avoid the risk of wastage. Thus, with D365 Business Central, production becomes a calculated and efficient process.

Challenge 2: Poor Inventory Management – A Recipe for Chaos

Inventory management feels like solving a puzzle without all its pieces, making it hard to complete the picture effectively. Too much stock can lead to higher storage costs and potential spoilage. This results in missed opportunities and dissatisfied customers. Moreover, many manufacturers lack the tools to track inventory effectively, leading to inefficiencies and financial strain.

The Solution:

With Inventory Management in Dynamics 365 Business Central, manufacturers gain full visibility into their inventory whether it is raw materials, work-in-progress items or finished goods. Automated replenishment ensures stock levels are always optimal, guided by demand forecasts and historical data. This feature not only minimizes storage costs but also ensures that critical materials are always available when needed.

Challenge 3: Inefficient Resource Utilization – Lost Productivity

Manufacturers often struggle to allocate resources like machines, manpower and materials efficiently. Misaligned schedules can result in idle equipment, overworked labour and operational bottlenecks that slow down production and inflate costs.

The Solution:

The Capacity Planning feature in Dynamics 365 Business Central ensures a balanced and streamlined approach to resource utilization. By optimizing production loads, scheduling machines efficiently and aligning workforce shifts with demand, it maximizes productivity. Additionally, predictive analytics allow manufacturers to adjust their plans proactively, ensuring operations run like a well-tuned machine.

Challenge 4: Limited Scalability – Hitting the Growth Ceiling

As businesses grow, so do their operational complexities. Small manufacturers often find themselves constrained by basic accounting tools and outdated systems that fail to scale with their needs. This limits their ability to manage production demands or navigate market changes effectively.

The Solution:

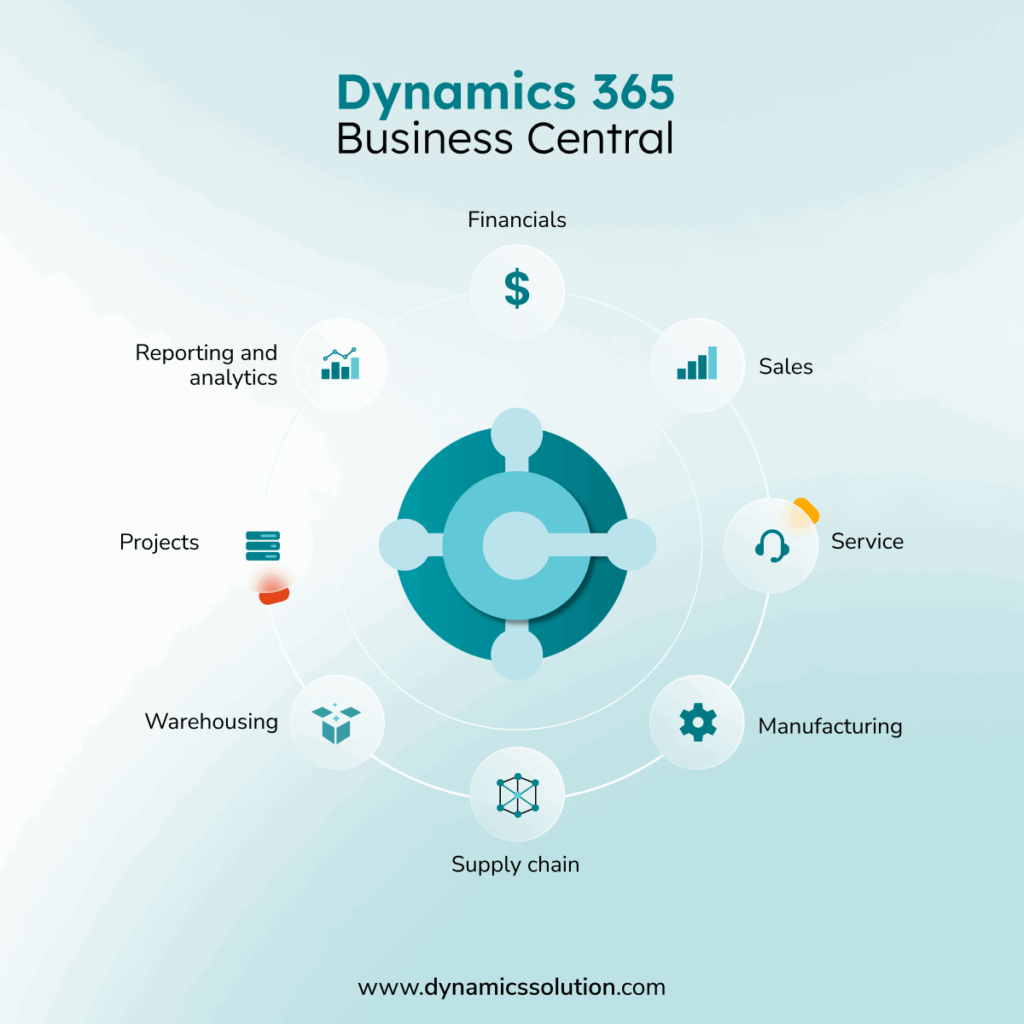

Dynamics 365 Business Central offers a scalable, cloud-based solution tailored to small and medium-sized manufacturers. It integrates key business functions like finance, sales, inventory and production into a single platform. This results in enabling seamless collaboration and data sharing across departments. Furthermore, it’s flexibility allows manufacturers to adapt to evolving needs, paving the way for sustainable growth.

Challenge 5: Lack of Actionable Insights – Flying Blind

Without data-driven insights, manufacturers are left grasping at shadows in the dark. Poor visibility into production performance, market trends and financial health can lead to reactive decision-making rather than proactive strategies.

The Solution:

Business Central leverages advanced analytics and AI-driven insights to provide manufacturers with a clear view of their operations. From forecasting sales trends to identifying bottlenecks and recommending improvements, it equips decision-makers with actionable intelligence. This enables them to make informed choices, stay ahead of market demands and drive long-term success.

Why Business Central is the Perfect Partner for Manufacturers?

Manufacturing isn’t just about producing goods—it’s about orchestrating processes, managing resources and delivering value. Dynamics 365 Business Central is the ultimate partner for manufacturers, addressing key challenges with smart and integrated solutions.

By offering features like Production Scheduling and Inventory Management, it transforms operations into a seamless flow. Furthermore, it’s cloud-based infrastructure, integration with Microsoft tool and customizable options ensure that manufacturers can not only overcome today’s challenges but also scale and adapt to tomorrow’s opportunities.

Empower Your Manufacturing Operations with Dynamics Solution and Technology

The manufacturing industry is a dynamic maze of challenges, but with Dynamics 365 Business Central, you’re equipped to navigate it with confidence. You can transform hurdles into milestones of success and let your operations illuminate the path to growth and efficiency like never before.

At Dynamics Solution and Technology, we specialize in helping manufacturers unlock the full potential of Dynamics 365 Business Central. From tailored implementations to ongoing support, we ensure that your operations are aligned with your goals.

Partner with us to turn your manufacturing challenges into triumphs and drive your business towards smarter, efficient operations.