Manufacturing is a complex ecosystem where multiple processes happen simultaneously, from sourcing raw materials to delivering finished products. One of the biggest challenges manufacturers face is keeping production lines and inventory systems tightly synchronized. Traditional methods often struggle with real-time visibility, leading to stock discrepancies, production delays and inefficiencies in resource allocation.

However, Microsoft Dynamics 365 Manufacturing addresses this challenge by offering a unified platform that connects production workflows with inventory management seamlessly. This integration isn’t just about data sharing; it empowers manufacturers to optimize resource utilization, gain visibility into every stage of production and respond swiftly to changes in demand or supply chain disruptions.

This blog explores how Dynamics 365 Manufacturing connects production lines and inventory systems, ensuring precision, efficiency, and scalability for modern manufacturing enterprises.

Inside the Numbers: Dynamics 365 Manufacturing’s Role in Industry Transformation

| Focus Area | Key Finding | Source |

| Financial Impact | Organizations using Dynamics 365 Manufacturing gain an average annual benefit of $20.6M, with a 3-year ROI of 301% | IDC, 2024 |

| AI & IoT Integration | By 2025, 50 billion devices will connect to the Industrial Internet of Things (IIoT); 70% of manufacturers use digital twins to optimize operations. | Industry Forecast, 2024-2025 |

| AI-Driven Agility | AI tools automate vendor management, predict shortages, and streamline purchase orders to maintain operational stability. | Market Research, 2024 |

Why Synchronized Production and Inventory Are Essential?

In manufacturing, linking production lines with inventory isn’t just helpful; it’s vital for smooth operations. When these systems work separately, it leads to delays, missing materials and inventory issues like overstocking or shortages. Here’s why it’s important:

Better Inventory Control

When inventory and production data are integrated, companies can ensure that the right materials are always available when needed. This avoids production stoppages, reduces machine idle time and improves overall productivity.

Smarter Cash Flow

Synchronizing production and inventory enables companies to reduce unnecessary stock and prevent costly shortages. This balance frees up cash flow for strategic investments and day-to-day operations, supporting both profitability and agility.

Data-Driven Decisions

Integrated data helps managers track usage trends, identify bottlenecks, adjust reorder level, and predict demand, reducing surprises, and improving planning.

Increased Efficiency

A synchronized system means less downtime, fewer rush shipments, happier customers, and smarter use of capital.

Future-Ready Manufacturing

Connected production and inventory enable quick scaling, easier adoption of automation and IoT, and keep companies competitive in fast-moving markets.

The Hidden Costs of Disconnected Production and Inventory Systems

some key challenges manufacturers face when connecting production lines and inventory systems without using tables:

- Stock Discrepancies: Without real-time tracking, inventory records often fail to reflect actual stock levels, leading to overproduction, shortages, and supply chain inefficiencies.

- Production Delays: Disconnected systems make it difficult to align material availability with production schedules, causing delays and inefficiencies in resource allocation.

- Manual Data Entry Errors: Relying on manual processes increases the risk of miscalculations, incorrect stock adjustments, and production workflow disruptions.

- Limited Visibility: Manufacturers often struggle to track raw materials, work-in-progress, and finished goods, making it difficult to optimize resource utilization and demand forecasting.

- Supply Chain Bottlenecks: Lack of integration leads to delays in procurement, inventory replenishment, and distribution, affecting overall production efficiency and customer satisfaction.

- Lack of Automation in Inventory Replenishment: Without predictive analytics, manufacturers risk overstocking or understocking, creating inefficiencies in cost management and material availability.

- Disconnected Data Flow Across Departments: Fragmented systems prevent seamless data sharing between production, inventory, and logistics teams, resulting in poor decision-making and misaligned workflows.

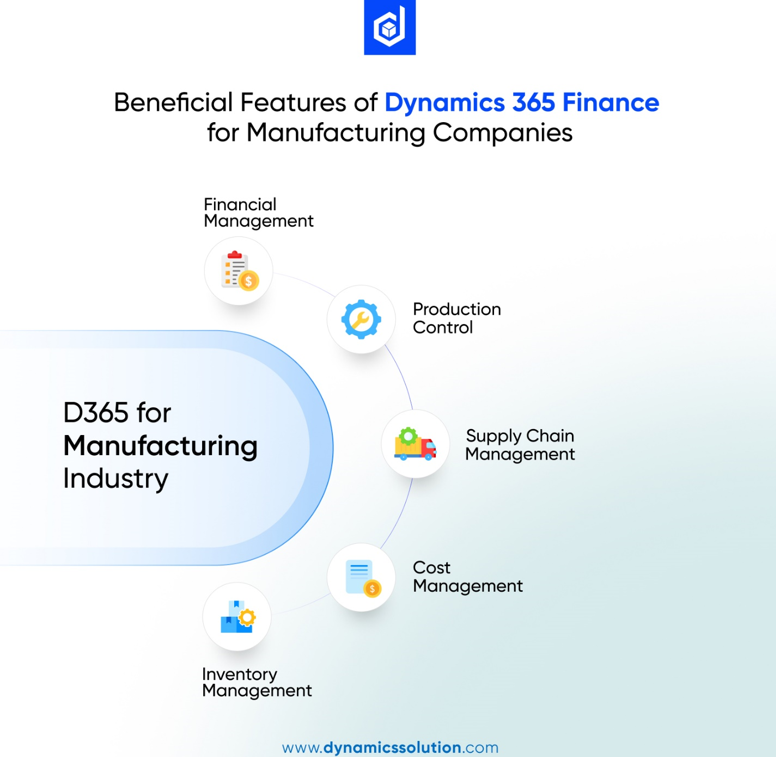

1. Real-Time Inventory Tracking

Dynamics 365 Manufacturing provides real-time visibility into inventory levels, ensuring that production lines have the necessary materials without delays or shortages.

- Automated stock updates prevent discrepancies between physical inventory and system records.

- Barcode and RFID integration streamline tracking of raw materials, work-in-progress, and finished goods.

- AI-driven demand forecasting ensures optimal stock levels based on historical data and market trends.

2. Seamless Production Scheduling

Manufacturers can synchronize production schedules with inventory availability, reducing downtime and optimizing resource utilization.

- Automated work order generation ensures materials are allocated efficiently.

- Dynamic scheduling algorithms adjust production timelines based on inventory fluctuations.

- Integration with procurement systems ensures timely replenishment of raw materials.

3. Intelligent Supply Chain Coordination

Dynamics 365 Manufacturing seamlessly links inventory management with supply chain logistics to keep materials moving smoothly through production. Features like real-time supplier updates improve collaboration, while automated reordering helps prevent stock shortages. Integration with warehouse systems optimizes storage and retrieval, and IoT-enabled monitoring provides real-time tracking of production efficiency and inventory flow.

4. Predictive Analytics for Inventory Optimization

By leveraging AI and machine learning, Dynamics 365 Manufacturing enables predictive analytics to optimize inventory levels and reduce waste.

- Historical data analysis helps manufacturers anticipate demand fluctuations.

- Automated replenishment triggers prevent overstocking and understocking.

- Cost analysis tools ensure efficient resource allocation and budget control.

5. Unified Data Flow Across Production and Inventory

A centralized data platform ensures that production teams and inventory managers work with accurate, real-time information.

- Cloud-based architecture enables seamless data sharing across departments.

- Automated reporting tools provide insights into production efficiency and inventory health.

- Role-based access control ensures secure data management across teams.

The Reality Check: Challenges of Implementing Dynamics 365 Manufacturing

Implementing Dynamics 365 Manufacturing offers clear benefits, but the journey is often lined with challenges that businesses need to tackle head-on. Here’s a detailed look at the real obstacles manufacturers face when introducing Dynamics 365 into their operations.

Integrating Legacy Systems

Many manufacturers rely on legacy ERP or custom tools that don’t easily align with Dynamics 365. Successful integration requires careful data migration and often custom connectors or APIs to bridge old and new systems. Without proper planning, this process can become a major bottleneck.

Driving User Adoption

Adopting new technology isn’t just about software—it’s about people. Employees accustomed to legacy processes may resist change, slowing implementation. Comprehensive training and ongoing support are key to building user confidence and ensuring smooth adoption.

Managing Real-Time Data Flow

Dynamics 365 excels at handling real-time production data, but integrating IoT devices requires network upgrades and careful management of data accuracy. Even small inconsistencies can disrupt production and decision-making.

Balancing Cost and Time

Implementing Dynamics 365 requires investment in licensing, customization, hardware, and dedicated project teams. While the long-term benefits often justify these costs, the upfront time and financial commitment can be challenging.

Ensuring Data Security and Compliance

With increased data sharing, protecting sensitive information is critical. Companies must enforce strict access controls, encryption, and comply with industry regulations to safeguard data and maintain trust.

Trusted Partners That Make Dynamics 365 Manufacturing Work for You

Navigating the complexities of implementing Dynamics 365 Manufacturing requires more than just software. It demands experienced partners who understand both technology and manufacturing operations. Here’s how reliable implementation partners help manufacturers achieve a smooth and effective transition:

Expertise in Manufacturing Processes

Experienced partners bring deep knowledge of manufacturing workflows and tailor Dynamics 365 implementations to match unique production needs. They develop integration strategies that seamlessly connect legacy systems with new platforms, ensuring minimal disruption. Their guidance on best practices helps streamline operations and improve overall efficiency.

Comprehensive Training and Ongoing Support

Successful adoption depends on well-prepared teams. Partners provide targeted training sessions, both on-site and remote, customized for different user roles and skill levels. They supply clear documentation and user guides to support smooth onboarding and maintain continuous technical support to quickly resolve any issues.

Scalable Solutions Designed for Growth

As businesses grow and production demands increase, implementation partners ensure that Dynamics 365 configurations are flexible and scalable. They assist in integrating emerging technologies like IoT and AI to drive smart manufacturing and help build future-proof systems that align with long-term goals.

Commitment to Data Integrity and Security

Data accuracy and security are vital in manufacturing environments. Trusted partners design secure data migration plans to reduce risks during transitions and conduct system audits to maintain data integrity. Additionally, they help configure the system to comply with industry regulations and standards, safeguarding sensitive production and inventory information.

Take the First Step Towards Smarter Manufacturing with Dynamics Solution and Technology

Connecting production lines and inventory systems is no longer a luxury—it’s a necessity for manufacturers looking to streamline operations, reduce errors, and drive efficiency. Microsoft Dynamics 365 Manufacturing offers the tools and flexibility to make this integration seamless, while experts like Dynamics Solution and Technology provide the knowledge and support needed to overcome challenges.

With a well-implemented Dynamics 365 system, manufacturers can achieve real-time visibility, data-driven decision-making, and a strong foundation for future growth.