The pressure on the manufacturing industry has been immense, due to the demand surge, labor politics and the competitive need to maximize production with decreased costs. Moreover, with economically and politically volatile landscapes, supply chains have become unpredictable too. These factors have induced the need for digital solutions that surpass the conventional hindrances in manufacturing and unlock maximized productivity.

Industry 4.0 and Internet of Things (IoT) emerged as viable solutions by digitizing the manufacturing processes and building smart factories to mitigate the counter-productive factors. According to a Deloitte survey, 83% of manufacturers believe that smart factories will reshape the manufacturing and production landscape in the next five years.

In this blog we will explore Azure IoT as a tool which empowers manufacturers with its smart capabilities and enables them to propel their manufacturing processes into the Industry 4.0 experience.

Why Does Manufacturing Need IoT?

The manufacturing industry has been evolving ever since humans began to make things. It has witnessed and withstood monumental transitions due to the four industrial revolutions with the core aim of improving operational productivity. However, in the present world technology has openly challenged conventional methodologies. It has compelled the world, from individuals to organizations, to synchronize themselves with technological advancements.

Similarly, technological advancements have highlighted some glaring challenges, within the manufacturing landscape, that were proving to be major hindrances in process optimization and increased productivity. These challenges are exactly what IoT aims to mitigate through smart factories, by bridging the gap between the digital and the physical world.

- To stay ahead of rivals swiftly digitizing their processes.

- To gain complete visibility across a resilient supply chain.

- To save costs by mitigating any possible disruptions in a high-stakes environment.

- To foresee and prepare for unanticipated

- To put the copious amounts of data generated to proper analytical use.

- To enhance workplace safety and automate processes hazardous for labors.

- To improve time-efficiency to meet the demand surge.

What is Azure IoT for Manufacturing?

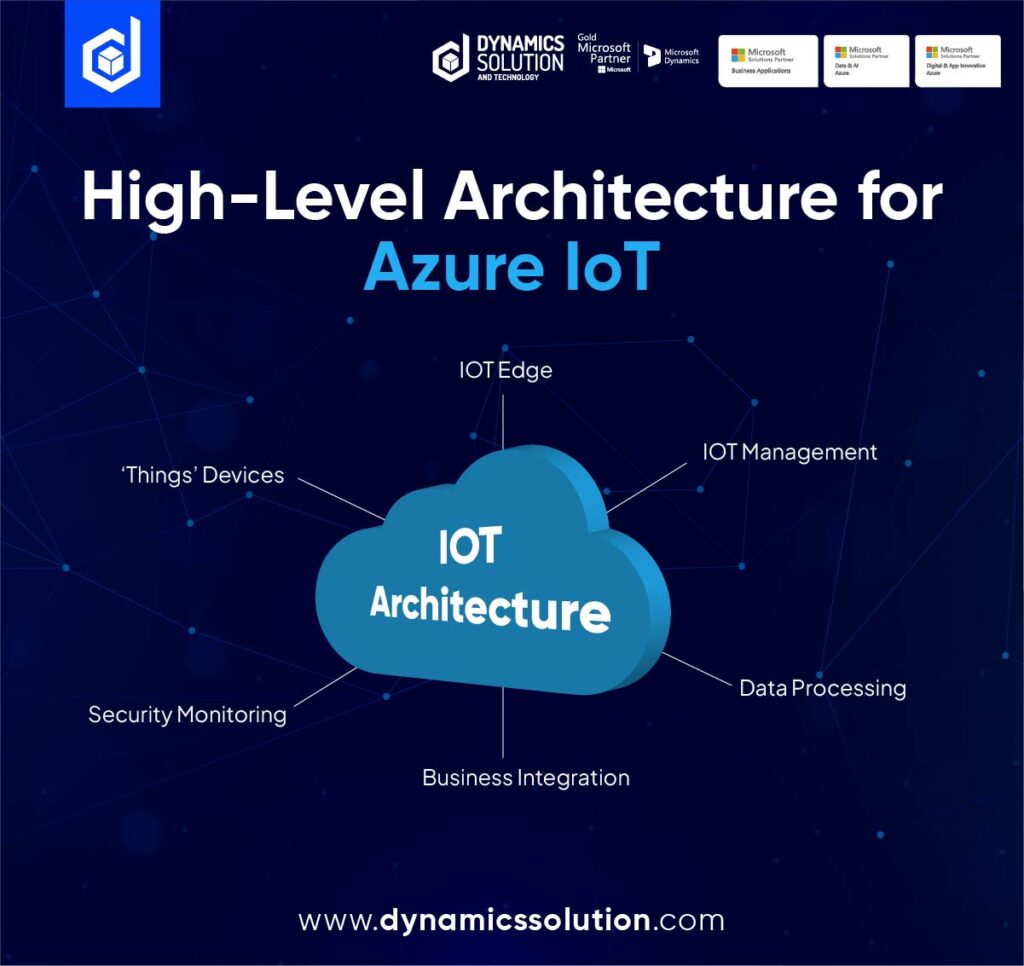

Azure IoT is a cloud-based suite of sophisticated tools that enable manufacturers to adapt the smart and agile methodology of production. Also known as IIoT (Industrial Internet of Things), it is more than powering manufacturing processes through the capabilities of the Cloud. Azure IoT for Manufacturing is an innovative confluence of Platform-as-a-Service (PaaS), intelligent edge computing, and Machine Learning (ML).

It collects data from industrial equipment sensors and sends it to a network which connects machinery, factory assets, data analytics, floor managers and other professionals. This network empowers machinery to analyze and report their shortcomings to the managers and are then guided to produce viable solutions, all because of intelligent edge computing and ML. The cloud-aspect of it empowers managers to oversee all the automation processes while being thousands of miles away from the field.

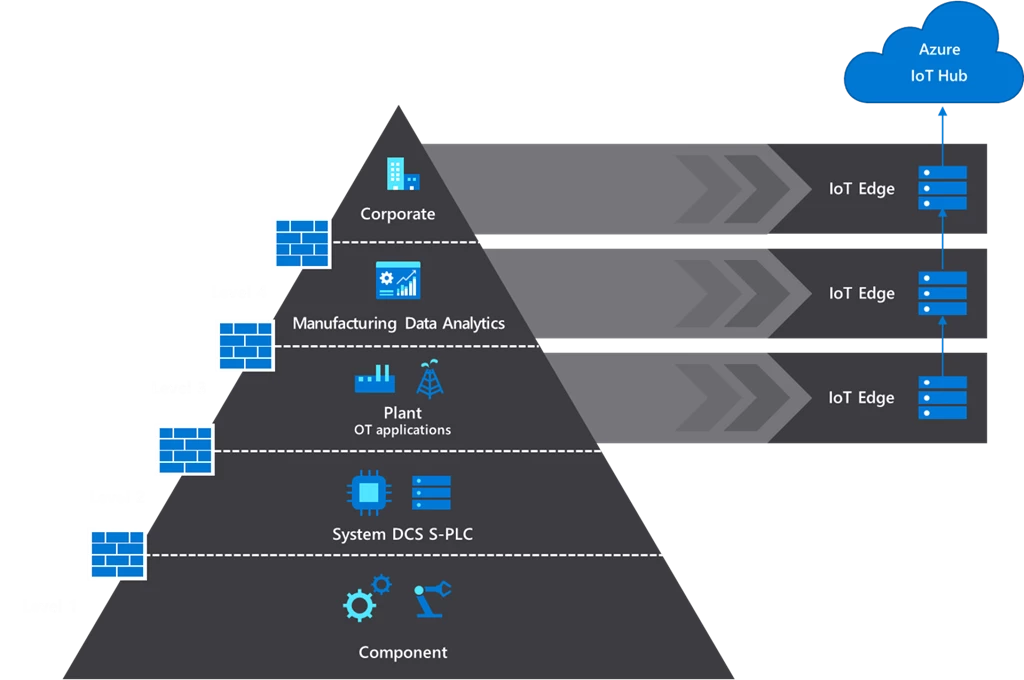

Azure IoT’s nesting capabilities allows organizations to establish hierarchy of IoT devices through an automation pyramid, without any safety concerns. This allows manufacturers to collect data, aggregate it and move it to the cloud without any hesitation.

Azure IoT for manufacturing unleashes an intelligent network of data, which is sent from one point to another with a collective aim of improving operational efficiency. This digital feedback loop enhances operations in real-time and mitigates data siloes. For example, customer data enhances product development, operational data informs and improves staffing decisions, and the sales data informs production. This intelligent flow of data makes the system more agile, safe and improves manufacturing and customer experiences.

Key Capabilities

The following are the key capabilities of Azure IoT which allows smart manufacturing through a hyper-connected network.

Top-notch Data Management:

Manufacturing professionals can seamlessly integrate their devices, sensors, and machinery together. This allows them to review the data from all the ‘things’ in one place. Data siloes and segregation can be seamlessly mitigated with Azure IoT.

Predictive Maintenance:

Manufacturing is a high stakes environment, and any unanticipated downtime means unfulfilled customer needs and losses incurred. Azure IoT helps manufacturers in being proactive rather than reactive. This means that they can leverage the capabilities of ML driven preventive analytics and mitigate equipment downtimes. ML models analyze factors like machine temperatures and their vibration measurements which helps them point out any anomalies and consequent risks.

Intelligent Quality Control:

ML models monitor set parameters that affect the quality of the manufactured goods. Factors like air quality, humidity and temperatures are monitored to be in set brackets and if any factor is inadequate, floor managers are notified and, in some cases, the factors affecting quality are bought under control by the smart equipment itself.

Asset Tracking:

Asset tracking is often a challenging task due to the large volume of assets that need to be tracked. Equipped with sensors for asset quality and trackers for locations tracking, managers can track their assets in one place due to Azure IoT.

Real-time Monitoring and Analytics:

The hyper-connectivity of assets, machinery and devices allows managers access to real-time data, which helps them remain up to date 24/7. Enterprise-grade analytics helps them make quick decisions and drive productive strategies. This also helps manufacturers pinpoint patterns and find areas of improvement.

Supply Chain Optimization:

Azure IoT helps factories make their supply chains resilient and optimized. By allowing real-time visibility, analytics and tracking inventories, manufacturers are well-informed regarding the conditions of their supply chain. This lets them stay ahead and take proactive steps in case of any disruption to the supply chain.

Enhance Workplace Safety:

Azure IoT helps automate processes, even those that are hazardous to labor safety. Instead of manual labor operating on the dangerous field, automation puts their safety on priority. The real-time monitoring capabilities lets managers be aware of any mishaps and accidents and take active measures to minimize them.

Make Your Factory Smart with Dynamics’ Solution and Technology

Industry 4.0 has been around for a couple of years and the current post-pandemic inflation has propelled organizations to turn their operations remote as much as they can. Large corporations have already invested in Industrial IoT and smart factories and are reaping the benefits as we speak. With its versatile use cases, it is high time that every factory adapted to IoT and smart processes, otherwise the chances of them being swept away by the fourth Industrial Revolution are extremely high. Moreover, with competitors having already invested in IoT and generating high revenues, the importance of digitally transforming your operations is monumental in 2023.

Let IoT bring you, a manufacturer, closer to your end-user and curate innovative ways to retain loyal customers. Dynamics Solution and Technology comes forth as your trusted ally. With our talented team of industry experts, we can make your journey to interconnected and automated processes seamless and swift. Our extended range of digitally transformed clientele in the Gulf and MENA regions is testament to our unwavering excellence.

Contact us now to become a part of Industry 4.0 with Azure IoT implementation and increase profitability today!