For small-scale manufacturers, overproduction is a significant challenge. When production exceeds what’s necessary, it leads to excess inventory, wasted materials and higher costs. This inefficiency can hurt profitability and cause problems in the production process. However, Microsoft Dynamics 365 Business Central can help small manufacturers optimize production schedules, manage inventory better and ensure production is in line with actual demand.

In this blog, we’ll look at how Business Central can assist manufacturers in preventing overproduction using key features like Production Scheduling, Inventory Management and Capacity Planning.

What is Overproduction in Manufacturing?

Overproduction is one of the key inefficiencies in manufacturing. It happens when the output of production exceeds customer demand or the amount of inventory needed, causing waste in the process. Small manufacturers often struggle with this because they might not have accurate demand forecasts or efficient production planning. The result can be:

- Extra inventory that takes up space and increases storage costs with a risk of spoilage.

- Wasting materials, labor and energy to make products that aren’t needed.

- Capital tied up in unsold goods which can negatively affect cash flow and hurt financial health.

Therefore, for small-scale manufacturers, having a solid production management system is essential to avoid overproduction and make sure resources are used wisely.

Why is Business Central Perfect for Small Manufacturers?

Microsoft Dynamics 365 Business Central is a comprehensive ERP solution designed for Small to Medium-sized Businesses (SMBs) that have outgrown basic accounting software. It helps manage a range of business operations, including finance, sales, inventory and manufacturing.

One of the biggest advantages of it is its cloud-based setup. Because it’s hosted in the cloud, manufacturers can access real-time data from anywhere and collaborate seamlessly across different departments. It’s also customizable, so it can be tailored to the unique needs of a manufacturer.

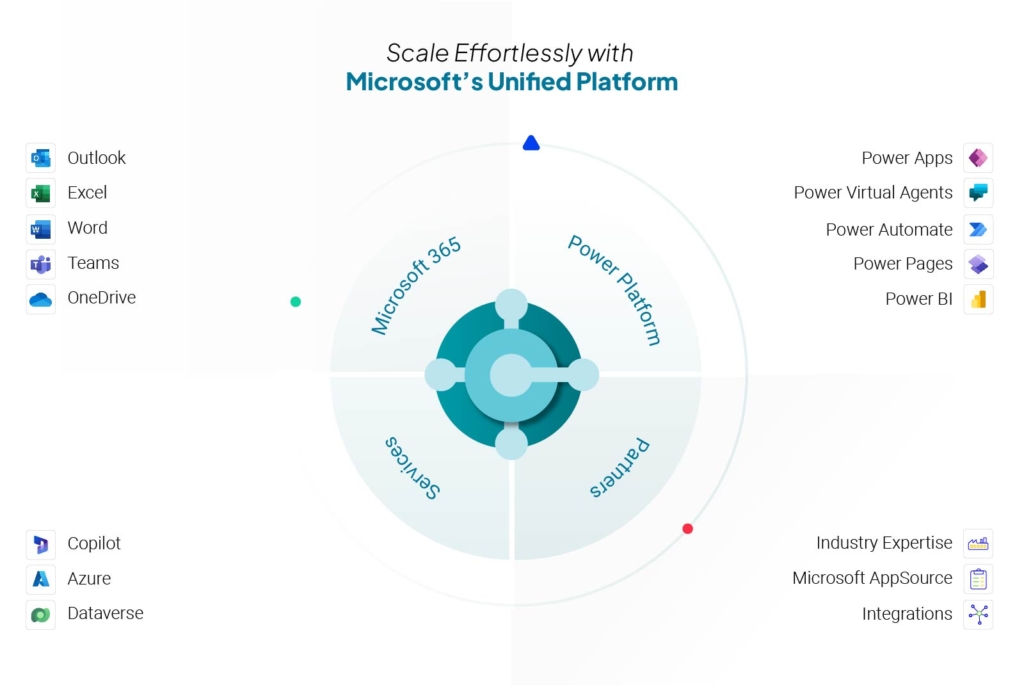

Plus, it integrates easily with other Microsoft tools like Excel, Teams and Power BI, so it connects with the tools that many businesses are already using. This flexibility allows businesses to only select the features they need whether it’s for production scheduling, inventory management or capacity planning.

Key Features of Business Central for Preventing Overproduction

1. Optimizing Production Runs with Real-Time Data

One of the main reasons overproduction happens is due to poor scheduling. Without up-to-date data and accurate forecasts, manufacturers often end up producing too much or missing deadlines.

Production Scheduling in Business Central helps prevent this. It provides real-time scheduling based on actual demand, syncing with sales orders and forecasts. This ensures that production is matched to demand and eliminates the guesswork. Production orders are automatically generated and if market conditions change, schedules are adjusted accordingly. Thus, by using real-time production scheduling, manufacturers can avoid the problem of overproducing.

2. Accurate Inventory Management

Good inventory management is essential in preventing overproduction. If manufacturers don’t track inventory levels accurately, they may over-order raw materials or end up with too many finished products.

It helps with this by providing real-time visibility into inventory. This includes raw materials, in-progress items and finished goods. Manufacturers can keep inventory at optimal levels, reducing the risk of overproduction or stockouts.

Additionally, the system has automated replenishment features. It uses demand forecasts and historical data to automatically reorder materials when stock drops below a certain level. This proactive approach ensures materials are available when needed while avoiding both shortages and excess stock. With accurate inventory tracking and automatic replenishment, manufacturers can prevent overproduction and reduce storage costs.

3. Balancing Production Resources

Overproduction can also result from inefficient use of resources, like machines, labor and shifts. If manufacturers don’t plan their capacity well, they may run machines too much or produce too many items.

Capacity Planning in Business Central helps manufacturers balance production loads. It ensures resources such as machinery and labor are used efficiently, minimizing waste. By aligning resource usage with actual demand, the system helps keep operations cost-effective.

It also helps with machine and work center scheduling. Production activities are scheduled based on machine availability, preventing bottlenecks and ensuring that equipment is used effectively.

Another valuable feature is production forecasting which uses historical data to predict future demand. With this feature, manufacturers can better plan their capacity needs and adjust schedules as necessary. This helps meet customer demand while avoiding overproduction. By using Capacity Planning, manufacturers can ensure resources are only used as needed, avoiding unnecessary strain on equipment and workers.

How Business Central Helps Small Manufacturers Scale and Grow?

As small manufacturers scale their operations, it becomes increasingly important to have a system that can manage complexity while keeping processes efficient. It is a powerful solution that helps SMBs in manufacturing to:

- Streamline Operations: With all key business functions integrated into one platform, manufacturers can streamline production processes, reduce delays and increase throughput.

- Enhance Collaboration: It fosters collaboration across departments, ensuring that sales, production and inventory teams are all aligned with the same data and goals.

- Improve Decision-Making: The system provides actionable insights into production, inventory and financial data, empowering manufacturers to make informed decisions and reduce waste.

- Adapt to Market Changes: It is flexible and can easily adapt to changes in customer demand, supply chain disruptions or production requirements, ensuring manufacturers stay responsive and avoid overproduction.

Achieve Manufacturing Harmony with Dynamics Solution and Technology

For small-scale manufacturers, preventing overproduction is critical to maintaining profitability and operational efficiency. Dynamics 365 Business Central offers an integrated solution that helps manufacturers optimize production scheduling, track inventory in real-time and balance production loads. By leveraging these key modules, manufacturers can prevent overproduction, reduce waste and make more informed decisions.

Moreover, it’s cloud-based infrastructure, integration with other Microsoft tools and customizable options make it an ideal solution for small manufacturers looking to scale their operations without the risk of overproduction.

At Dynamics Solution and Technology, we specialize in delivering tailor-made implementations for growing SMBs. Our team works closely with you to understand your unique production challenges and customize the solution to suit your business. We don’t just implement an ERP system; we help you transform your manufacturing operations into a finely tuned and efficient process.

Partner with us to unlock the full potential of Dynamics 365 Business Central.