Modern manufacturers continue to look for innovative and sustainable solutions to encourage organizational growth, enhanced productivity, and bolster their bottom lines. Today’s world sees the manufacturing industry with added complexities; products, interconnected supply chains, and meeting the requirements of tech-savvy customers. With the expectations swinging high, the manufacturing industry cannot afford to run into any issue that may affect its productivity levels and slow it down.

Nevertheless, the competitive and dynamic nature of the versatile manufacturing industries makes for a challenging environment. Thereby the comprehensive capabilities of the ERP and CRM solution, from the Microsoft Dynamics 365 suite, help the organizations make informed and strategic decisions, all while holistically viewing the supply chain processes in a single solution.

This blog carefully unfolds the success-centric insights of Microsoft Dynamics 365 for manufacturing solutions as organizations are willing to overcome challenges head-on to ensure that they not only survive but also thrive.

Manufacturing Industry Challenges to Watch Out

The manufacturing industry is commonly sighted to have faced numerous challenges with ongoing fluctuations in commodity prices, labor rates, technology, tariffs, and duty applications. Nevertheless, manufacturing industry leaders continue to bridge this gap and enhance the workforce experience.

Manufacturing Skills Gap

The manufacturing industry is forecasting significant growth in the upcoming years. Back in 2018, Deloitte published a joint report with The National Association of Manufacturers (NAM) citing that the industry needs to fill resources for 2.4 million jobs by 2028. Over the course of years, around 803,000 job positions have recovered.

However, the industry is constantly looking to acquire talented employees to bridge the gap and meet true potential levels.

Machine Intelligence and Tech Growth

The manufacturing industry is continuously growing, expanding in numbers, and taking a hold of technology. Industry-wide implementation of smart machines assists companies in collecting data inputs, swiftly processing them to improve productivity, and implementing predictive maintenance.

With industries working on data mining capabilities of machine intelligence, it consistently improves productivity with increased frequency while collecting and analyzing the data to formulate meaningful decisions.

Managing Inventory and Supply Chain

Inventory and supply chain management continues to be one of the most crucial and time-binding tasks. Any mismanagement leading to a fluctuation in the inventory can cause direct damage to the profit levels and client relationships. Similarly, holding a large amount of inventory adds up to the warehouse costs. Keeping the inventory flowing calls for adequate investment in the tools, software, and processes to help the manufacturers save time and money.

Hence manufacturers are embracing digital transformation.

Digital transformation allows manufacturing industries to holistically monitor and manage the flow of inventories. The dedicated lines of inventory management provide valuable insight to prevent inventory issues and keep the flow in check.

Real-time data insights reduce the risk of supply chain interruptions and ensure that the process remains agile.

Customer Self-service Applications

One of the most common goals of all manufacturing industries is to timely deliver commodities to their customers. A contributing factor toward profit and revenue maximization, synchronized data allows real-time updates on the self-service application to communicate and track the status of the product.

The incorporation of a self-service customer application seamlessly tracks and accepts the tasks assigned without bothering anyone. It eliminates the need for the customer to connect to a live agent, reduces the workload on the support team, and helps users resolve basic customer issues.

- Better customer service

- Decreased customer support costs

- Faster customer resolution times

- More productive support staff

- Round-the-clock support

The emergence of Dynamics 365 for Manufacturers and Distributors

Manufacturers have increased their digital investment over the past years and accelerated the adoption of emerging technologies. Although companies with greater digital maturity showcased an increased level of resilience with more power to pivot and adapt to supply chain challenges. Continued investments, like the adoption of Microsoft Dynamics 365 in advanced manufacturing technologies can help develop the required agility.

In a world, where organizations are looking forward to sustainable ways to work smarter and faster while remaining equally competitive in the marketplace. The capabilities of Microsoft Dynamics 365 for manufacturing fill the gap between the CRM and ERP systems, bestowing manufacturers with ease to increase their speed of doing business and launch better products.

Encapsulating the Benefits of D365 for Manufacturing

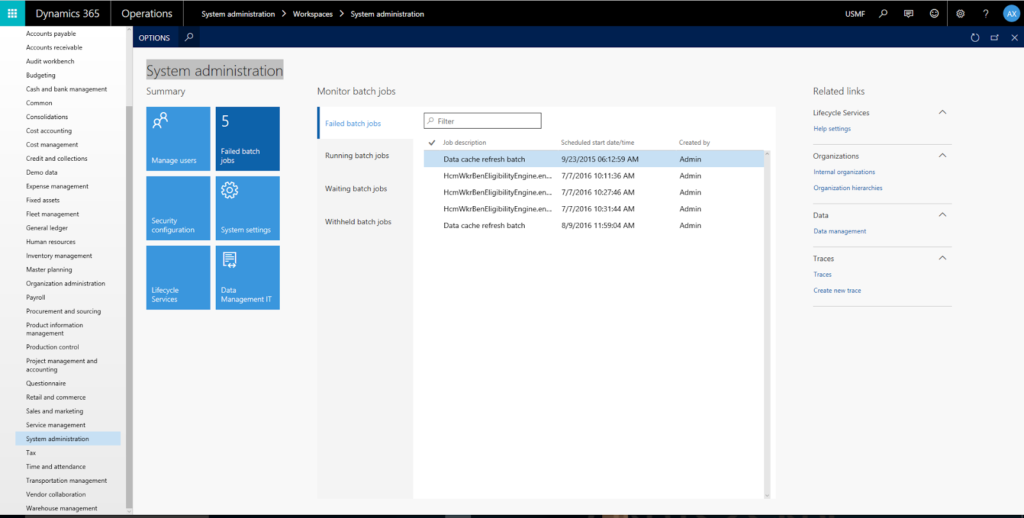

Microsoft Dynamics 365 unifies numerous aspects along the manufacturing lifecycle to improve outcomes and ensure digital business transformation. Along with rich analytics, embedded intelligence, and convenience, manufacturers can enable robust project management, get visibility into operations, empower employees, improve business productivity, and deliver personalized service.

Here are some of the popular benefitting features of Microsoft Dynamics 365 for manufacturing solutions:

Enabling Robust Project Management

Effective project management strategies holistically capture the cost, effort, and revenue metrics to achieve project goals. The inclusion of Microsoft Dynamics 365 for Manufacturing operations allows managers to foresee the production performance using insights from Power BI. The analytical dashboard allows the user to review, monitor, and approve all the time and cost-sensitive projects while calculating the profits and managing the KPIs simultaneously.

According to a report by McKinsey (2021), the market for big data in manufacturing is expected to reach $4.55 billion in 2025. This is a clear reflection of the inclusion of analytics insights into business processes to gain visibility into performance and operations to make faster and smarter decisions.

Similarly, D365 enables intelligent and relevant skills-based assignments with real-time visibility for a unified scheduling engine, accurately measures utilization, and makes intelligent decisions to get the most out of billable resources.

Enhanced Operational Visibility

Driving business excellence calls for complete operational visibility. From data collection, integration, and visualization of the global supply chain management, D365 allows businesses to gain end-to-end visibility and optimize processes when needed. The end results. Digital transformation fundamentally improves communication between production, supply, service, and sales.

Fostering such a level of department-level collaboration allows senior managers to view company metrics and the breakdown that can further improve operations.

Infusing Innovation for Employee Empowerment

Empowering employees with the necessary digital tools and skill opens unlimited possibilities for the advancement of businesses in the digital age. Entrusted with the right tools and software, the productivity and efficiency of the employees increase.

Automation empowers employees to contribute their best by minimizing time spent on repetitive tasks, increasing focus on innovation and value-added activities, and enhancing safety.

Microsoft Dynamics 365 provides role-specific tools and a 360-degree view via the dashboard, to adapt and enhance their working styles. It also connects the structured flow of the business processes with the unstructured work of collaboration and ultimately achieves a greater productivity level. Employees can then leverage their expertise for employee attraction, engagement, development, and retention. Hence, the B2B clients receive expert advice and seamless digital business transformation, along with a personalized solution.

Comprehensive, yet Personalized Solutions

In today’s highly competitive world, manufacturing industries look for a sustainable, yet personalized solution. With the inclusion of Microsoft Dynamics 365 for Manufacturing, B2B clients are promised value-added customer service that ensures quick and automated resolution without high-value interactions.

Embedded with the capabilities of the CRM and ERP, it unites several aspects of the business along the manufacturing lifecycle and supplements it with components of Power Platform to elicit rich analytics, and embedded intelligence, and add convenience via digital transformation.

Moreover, it is comprehensive in nature and allows the managers to investigate each customer’s journey, all while anticipating their needs, personalizing their interaction, and delivering value at every touchpoint.

Digital Transformation with Microsoft Dynamics 365 for Manufacturing

Microsoft Dynamics 365 is continuously helping the manufacturing organization tackle the ongoing challenges as they route towards utilizing the opportunities of tomorrow. Delivering an end-to-end combination of CRM and ERP systems, D365 combines with next-generation business applications targeted at core industry capabilities. Together, it helps navigate disruptions by increasing supply chain visibility and improving insights, all while helping the manufacturers build the necessary level of resilience and agility to succeed.

In all, the organization-wide integration delivers a clear picture of the promising digital transformation, enabling a customer-centric approach while optimizing operations.

- Optimizing supply chain operations through visibility and operations

- Streamline the management of assets, products, and productions

- Engaging customers in powerful new ways

- Transforming service centers into profit centers

This bestows manufacturing experts to gain insights and innovate faster. The inclusion of such a data-driven approach accelerates the cycle of innovation and delivers personalized B2B services to clients. Nevertheless, the implementation calls for an expert’s input to seamlessly deploy a data-driven tool and ensure that the goal of organization-wide digital transformation is met.

Ushering Growth with Dynamics Solution and Technology

Manufacturing industries are welcoming the rise of data-driven and automation tools. Amidst them, Microsoft Dynamics 365 truly remains a promising and sustainable solution for the manufacturing industries.

Nonetheless, converging with an adequate digital transformation partner with open swift paths of implementation and eliminate the possible redundancies.

Dynamics Solution and Technology provides an all-in-one solution to get started with your digital transformation journey. Being a Microsoft Gold Partner, it provides industry-specific solutions, personalized according to client-specific requirements for value-added processes and an increased ROI.

Our dynamic solutions for your manufacturing industries are embedded with the capabilities of CRM and ERP platforms. It increases supply chain visibility and insights, all while improving organizational agility to help the companies manufacture and operate smoothly and profitably.

Want to know what Dynamics 365 can do for your manufacturing industry? Connect and witness the digital business transformation yourself!