As the global recovery gains traction, demand for key raw materials, intermediate inputs, and logistical services has outstripped available supply, leading to rising and volatile prices, and delivery delays. The resulting mismatches have put supply chains under pressure, causing bottlenecks when the demand for an upstream production input suddenly and significantly exceeds the maximum amount that can be produced and delivered. Current bottlenecks have persisted longer than anticipated, weighed on output growth, and helped to raise global inflation.

Amidst all these challenges, organizations are increasingly struggling with change management as they plan to tread on a path toward digital business transformation.

Within an organization, the daily operational activities concerning goods and services stand as a pivotal segment. Even a minor error in this domain can lead to significant disruptions in delivery timings and dissatisfaction of customers.

To mitigate these challenges, Microsoft has introduced Microsoft Dynamics 365 Supply Chain Management, a user-friendly software tailored to help organizations build a resilient, sustainable, and predictable supply chain and ease their burden of managing and migrating data manually.

With this, the blog shares insight into how the adoption of Microsoft Dynamics 365 Supply Chain Management remains the first step towards eliminating supply chain redundancies and maintaining holistic efficiency across all aspects.

Exploring the Troubled Waters of Supply Chain

No matter the size of the impact of disruption, manufacturing, and supply chain industries dedicate thousands of man-hours and resources to maintain productivity, reliability, and on-time delivery for customers. But even with the amount of time and effort invested in eliminating these hurdles, it’s natural for the supply chain to incur disruptions at any point in the company’s value chain. In fact, it all comes down to the company’s resilience in how it responds and adjusts to these disruptions.

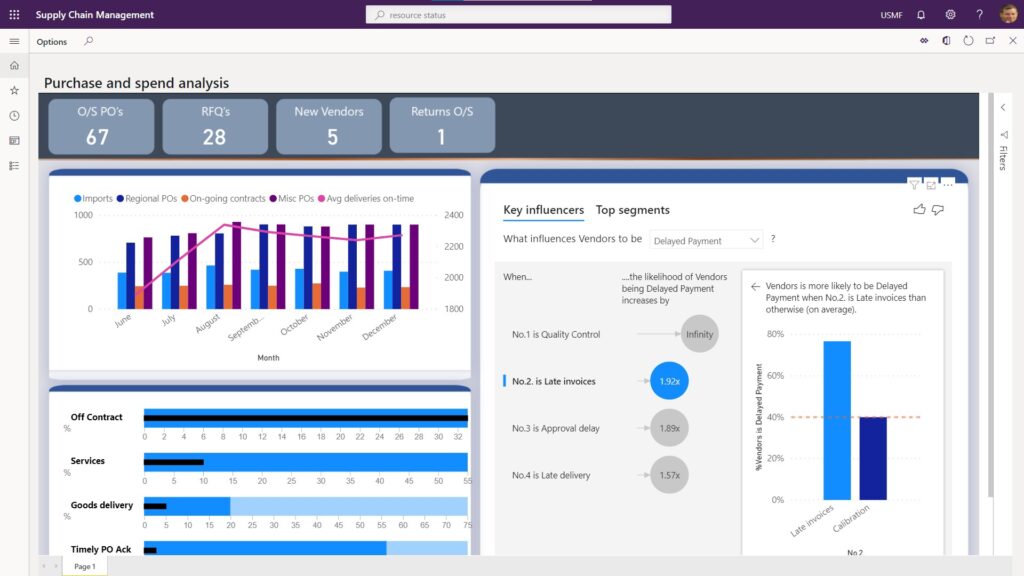

The inclusion of Microsoft Dynamics 365 Supply Chain Management allows organizations to integrate data from different sources and provide real-time analytics. With the dashboard providing a holistic view of the organization, business users can easily locate supply chain bottlenecks and take proactive measures to optimize the supply chain.

Here is a breakdown of how the capabilities of Microsoft Dynamics 365 Supply Chain Management help eliminate supply chain inefficiencies and redundancies.

Chaotic Overcrowded Ports

Port Congestion is the new reality for global ports and a major crisis that has become prevalent in the global industry in recent years. With 77% of major global ports staring down snarling backlogs, there is an urgent need to prevent unstable and tense supply chains from toppling into any further chaos.

Along with congestion, high operational costs, and low efficiency rates are constantly increasing. Fleet and service planners who need to keep costs down work with variable freight rates that rise and fall based on market rates, making it difficult to predict long-term costs. Also, bunkers account for a large share of total costs and need to be managed efficiently to keep costs down and maximize profits.

Microsoft Dynamics 365 Supply Chain Management offers real-time visibility, agile planning, and advanced data-driven insights to deal with chaotic and overcrowded ports.

This makes it easy to track inventory orders, monitor shipments, and respond to bottlenecks swiftly and in a timely manner.

Lags in Port Terminal Operations

Additional pressure on port terminals to cater to the high volume of customers and container consignments requires seamless operational efficiencies to work within the agreed turnaround times. Port terminals have business, and it witnesses fluctuations throughout the year. These changes may cause peaks in volume or lengthen the container delays, which finally impact the terminals’ ability to plan and execute the plan.

Microsoft Dynamics 365 Supply Chain and Management keeps track of the volume peaks throughout the year. It allows the businesses to manage their supplies accordingly so that they no longer have to face long waits or excess inventory costs.

Poor Supply Chain Visibility

One of the most common causes of supply chain bottlenecks and port congestion is directly linked to poor visibility. In times of hurdles and disruptions, the lack of visibility aggravates problems as businesses can neither determine the cause nor take corrective action.

Microsoft Dynamics 365 Supply Chain and Management delivers end-to-end supply chain visibility while ensuring inventory availability matches the desired service levels.

- Manage attribute-based omnichannel sales pricing

- Evaluate costs in discrete manufacturing using standard cost

- Calculate available to promise (ATP) up to three months in advance with Inventory Visibility.

Sustainability Concerns

Sustainability in the supply chains is a relatively new philosophy, and governments across the globe are striving to achieve sustainability in everything to save the planet. Various countries are implementing regulations on the risks associated with environmental, social, and governance (ESG). These regulations are fluid and are subject to changes.

For most of the companies, their lowest-level suppliers are from undeveloped countries where the governments are not enforcing sustainability initiatives, and they are only driven by cost. Identifying such suppliers and correcting their processes or replacing them with green suppliers will consume time, and that action can often cause supply chain disruptions.

Another approach is to opt for a circular economy model, helping build supply chain resilience in the face of disruptions.

- Remove waste, complexity, and toxicity from products for more effective end-of-life resource management.

- Keep raw materials in use for as long as possible and at their highest quality.

- Return materials into the environment with a positive impact.

Applying the circular economy could unlock trillions of dollars in the global economy, create hundreds of thousands of jobs, and lead to millions of tons of avoided emissions.

Initiating this change may be challenging but can be overcome by establishing a solid partnership with all the suppliers. Also incorporating Microsoft Dynamics 365 Supply Chain Management helps bring all the suppliers on one page and manage them easily.

Manual Vessel and Service Scheduling

Complicated patterns of manual vessel and service scheduling further compound the problem. The tremendous task of scheduling vessels optimally using manual or outdated systems, while still trying to keep costs down, is not only redundant but also adds to operational inefficiencies.

In times of demand-supply fluctuations, schedule reliability takes a big toll as the liner companies experience blank sailing and idling of ships. Microsoft Dynamics 365 Supply Chain Management allows port operators to plan how they will meet supply with demand and match cargo schedules on a real-time basis, thereby reducing the ever-increasing operational costs.

Fluctuating Demand and Freight Rates

Unexpected fluctuations in the demand and freight rates directly trigger bottlenecks. If a sudden spike in consumer demand pushes retailers to boost inventory on hand, manufacturers may struggle to keep up with production requirements. Similarly, a drop in demand can leave businesses with excess stock, leaving less space and resources to house new products and creating a bottleneck within the warehouse.

Microsoft Dynamics 365 for Supply Chain Management harnesses the data-driven AI capabilities of automation and machine learning to assess past patterns, consumer behaviors, and online search trends to increase demand forecast accuracy and reduce the risk of stockouts or excess inventory.

Microsoft D365 Supply Chain Management | Easing Supply Chain Congestion

As the hub connecting global production and consumption, ports play a pivotal role in the global maritime supply chain system. As a result of global events, the efficiency of supply chains has been reduced drastically. However, the adoption of Microsoft Dynamics 365 Supply Chain Management has emerged as the beacon of hope, promising to restore reliability to shipping schedules and breathe new life into global supply chains.

Proactive Monitoring

Companies can gain more accurate information about warehouse usage and product availability. It enables a more reactive digital infrastructure that lets users access real-time data about existing stock, throughput, and supply streams.

Holistic Container Visibility

Shipping ports need to line up containers in sync with the priority of perishable products and non-perishable goods. AI helps prioritize these containers with deep insights to avoid loss and wastage and thus intelligently handle container allocation.

Seamless Communication with all stakeholders

This fusion of data facilitates effortless communication among all stakeholders in the supply chain, ensuring that everyone is synchronized and ready to act swiftly and prevent congestion bottlenecks.

Inclusion of Automation Solutions

Robotic automation marvels expedite container movement, eliminating time-consuming processes like shuffling multiple containers to access a specific one designated for a particular truck, all managed from your dashboard.

Ensuring Safety Management

Safety takes precedence as sensors blanket port areas, continuously monitoring potential hazards, from heavy machinery to toxic gases, and tracking environmental conditions like weather and wind.

Risk Assessment

Providing accurate predictions about hazardous areas empowers vessel captains with timely warnings, safeguarding both personnel and cargo.

Dynamics Solution and Technology | Boosting Ports and Terminal Efficiency

Organizations are continuously reimagining their operational strategies in hopes of revitalizing their bottom line and retaining their customer base. The inclusion of Microsoft Dynamics 365 Supply Chain Management revitalizes your flow of goods and services through the value chain.

Dynamics Solution and Technology provides promising implementation services, with data migration security and swift system upgrades without any redundancies. Being a Microsoft Gold Partner, it has expertise in connecting your procurement and transportation management systems to your business landscape that anticipates bottlenecks before they occur and avert losses and missed deliveries for optimal performance.

Connect today and ease your supply chain for a sustainable and efficient performance!